One For The Motorheads: 45 Interesting Facts About Vehicle Engines

Everything that moves has an engine. There are engines in cars, motorcycles, locomotives, and sometimes even in strange, static objects like air conditioners. The invention of the engine has helped shaped modern society, and everything with an engine has our utmost admiration.

That moment when a properly maintained engine purrs to life is a different kind of bliss – especially when you’re late for work!

So here are a few awesome facts about some awesome engines. We hope you will be amused, but our main goal is to help you learn a bit more about these fascinating components. After all, every vehicle enthusiast should know something about engines.

Some of the items on this listicle include the biggest engines ever built, while others are the smallest or simply the most effective ones.

The first steam engine

In the early days, steam engines relied on horse-drawn rail carriages to pull them around. That’s because they could not move through rugged terrain. And then Peter Cooper created the “Tom Thumb,” a more effective steam engine with a top speed of 18 mph, in 1830.

A horse-drawn train approached the new engine as it was being tested and dared it to a race. The horse-drawn train finished the race first after taking the lead swiftly from the Tom Thumb, which snapped a belt. The next year, a better steam locomotive hit 30 mph.

Commercial jet engines’ lifespan

Two factors are often used to determine engine life in airplanes: flight hours and flight cycles. An entire flight cycle consists of takeoff and landing. The Time Between Overhaul (TBO), which is the manufacturer-recommended interval during which the engine is disassembled, is fully examined.

Any damaged parts are changed if necessary. This is the most crucial notion in engine life. The engine is typically cleared until the following TBO after an overhaul. Technically, an overhauled engine is equivalent to a fresh one in terms of performance, life (TBO), and guarantee.

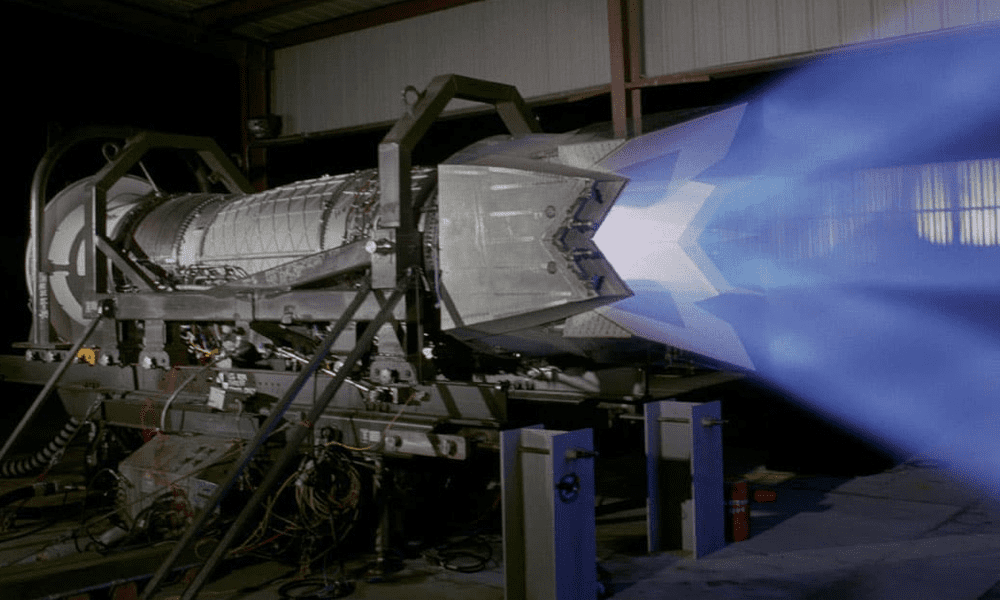

A powerful commercial jet engines

The GE9X, which will be installed on the Boeing 777X, has long held the title of the biggest jetliner engine in the world. It’s now also acknowledged as the most powerful. The engine produced an amazing 134,300 pounds of thrust during one trial run in 2017.

Nearly the same or more thrust was generated by the Soyuz rocket, which launched the first Russian astronaut into orbit. After years of developing the engine, researchers were able to increase the fuel efficiency by 10% thanks to new technology and materials.

Four types of common car engines

Internal combustion engines are found in the majority of vehicles. However, their configuration might change depending on how much capacity a maker wants the automobile to possess or if they want to make sure the engine can fit in the area allowed. There seem to be four basic cylinder layouts.

The cylinders can be placed parallel to the automobile in a straight layout or side by side and upright in a line layout. Another layout is to set the cylinders at a 60-degree angle in the V-type, or maybe they are placed horizontally in a flat layout.

A Top Fuel engine

The Top Fuel engine produces so much horsepower that no dynamometer within the earth can compare. Experts in several fields have struggled for years to determine a precise and undisputed horsepower figure. The numbers increased significantly as horsepower and technology advanced over the years.

This engine went from two thousand horsepower in the 70s to more than double that number in the following decade to 8,000 horsepower in the 1990s. A few years ago, computer modeling data was presented to demonstrate that such engines had ultimately surpassed the 10,000-horsepower threshold.

The effect of the number of cylinders in an engine

The exact number of cylinders present in an engine influences how much power it can generate. Twin-cylinder engines have the simplest engine layout; however, they don’t have much capacity or power. They do, nevertheless, occasionally appear on more compact and eco-friendly machines.

Three-cylinder engines are typically observed on smaller cars or hatchbacks, and they normally have a linear engine arrangement. Four-cylinder engines are the most prevalent and can be found in a wide range of small to midsize cars. Six to eight cylinders are found on supercars and race cars.

A huge and reliable jet engine

The 777 aircraft models are propelled by GE90-115B engines, which are licensed to provide an exceptional 115,000 pounds of thrust. This engine has almost 100% departure efficiency and has not yet had any in-flight shutdowns. There have been only two designated engine replacements, with no forceful engine relocations.

Emirates Airlines is a great illustration of the dependability of the new engine. Emirates started operating the 777-300ER in 2005 and currently has 16 of them in its fleet. There was only one engine-related disruption, and there were no engine replacements throughout that time.

Cold weather and engines

On chilly days, your car’s engine needs more time to warm up to its optimum working temperature. Short excursions are especially problematic because the automobile will spend most of those trips operating at less-than-ideal temperatures, which negatively affects fuel economy.

If you have a garage, make sure to leave your car there overnight to avoid this from happening. This will maintain a moderate and constant start-up temperature, reducing the load on the battery and preserving the fluidity of the engine oil.

Origins of the term horsepower

Thomas Newcomen’s 1712 design for the first industrial steam engine was significantly improved by Scottish engineer James Watt. The professional then got back to work, trying to elaborate a straightforward explanation of the capacity of his upgraded steam engine for his possible clients who wouldn’t understand the technical terms.

Watt made a decision. He asserted that one of his upgraded steam engines could generate enough power to substitute ten cart-pulling horses. This 10 “horsepower” came after performing some rudimentary calculations. This is the origin of the word “horsepower,” which has now become a mainstay.

How much does an airplane engine cost?

Makers of jet engines do not openly disclose the price of their goods. The scale and operational specifications of an engine have a significant impact on the price. A piston engine utilized on a modest general aviation aircraft like the Cessna 172 could cost between $40,000 and $70,000.

Larger turboprop engines need substantially more horsepower and can cost between $700,000 and $1.5 million. Several of the biggest airliners are powered by huge turbofan engines, which are far more substantial and sophisticated. These engines have a price range of $25 to $45 million. See why flight tickets are so pricey nowadays?

We’re getting Cyberpunk 2077 vibes

The Maserati V8 engine powers this behemoth in the image. The French coachbuilder Lazareth, which also made the absurd Ferrari-powered quad bike, is returning with more of its drivable super-machines. It is comparable to the 2003 premiere of the Dodge Tomahawk prototype quad fueled by a Viper.

Despite having four wheels, the biker may still tilt into curves. This allows the exploitation of those additional tires. According to Lazareth, the motorcycle’s V8 engine produces an outrageous 470 horsepower and 457 lb.-ft of torque. That’s some serious heat packed into this frame.

Pricing an engine

The structure and size of a problematic engine, the trade rate at the place where you’ve chosen to have the repair done, or whether you choose to substitute it with a secondhand, reconditioned, or new engine all have a big role in determining the impact on your budget.

Among the most crucial factors is the vehicle’s make and model. A new 4-cylinder engine typically costs roughly $4,000, a V6 about $5,000, and an 8-cylinder engine about $7,000 or more. A used engine can be obtained for a much lower cost, frequently between $400 and $700.

Keeping commercial jet engines in good condition

Vibration, friction, hot internal temperatures, oxidation, and physical harm from ingesting foreign material all contribute to the wear and tear of jet engines. Metal fatigue may result from all of this combined with the physical strain of quickly spinning engine components.

Aircraft engines must undergo regular maintenance. The process is meant to keep the engine in good shape and determine whether maintenance or part substitutions are required. Jet turbine blades, vanes, and other aircraft parts can have their lives prolonged through care, maintenance, and overhaul (MRO) procedures.

Four-stroke engines

A four-stroke engine uses four distinct piston movements to complete one operational cycle. To perform a task, a four-stroke engine needs two crankshaft rotations (720 degrees). The four-stroke engine type for motorized land transportation is the most popular internal combustion engine type.

It is used in cars, lorries, diesel locomotives, small planes, and motorbikes. The two-stroke cycle is the preferred alternative design. In some regions, the usage of four-stroke engines in automobiles and other forms of transportation is slated to end because of greenhouse gas emissions.

How the term “hangar” came into being

The wings of earlier aircraft were supported by cables that could be adjusted and released as needed to put the flight surfaces in the proper settings. This was known as “rigging.” The earliest aircraft were constructed out of wood and canvas.

The quickest method for accomplishing this was to dangle the aircraft from a position where the center of gravity ought to be and place the aircraft’s weight there as if it were in flight. This building became known as the “hangar,” and the term never went away after that.

A computer component in an automobile

In 1957, the Rambler Rebel, an odd design with a powerful power-to-weight ratio, delivered 0-to-60 mph acceleration that was second only to the Corvette. The Bendix Electojector, the very first electronic fuel injection device for production models, was the Rebel’s defining quality.

But weirdly, it was never implemented into production. The Bendix system, which was created during the very initial periods of solid-state circuitry, employed breaker points for triggering the fuel injectors and had other rudimentary characteristics that made it unsuitable for commercial use.

One of the highest-revving engines

It has been boasted that the Atom 500 offers one of the greatest power-to-weight ratios of any production model. This powerful engine has five valves per cylinder, an all-aluminum structure, and a dry sump to produce more than 500 bhp at 10,000 rpm.

The Atom 500’s intercooler has a distinctive color palette for the bodywork, wheels, and frame. It also has carbon composite paneling, aerofoils, and an incorporated steering wheel with Dymag magnesium wheels. It has a 2.9-second 0–60 mph time. It’s an absolute beast in every respect.

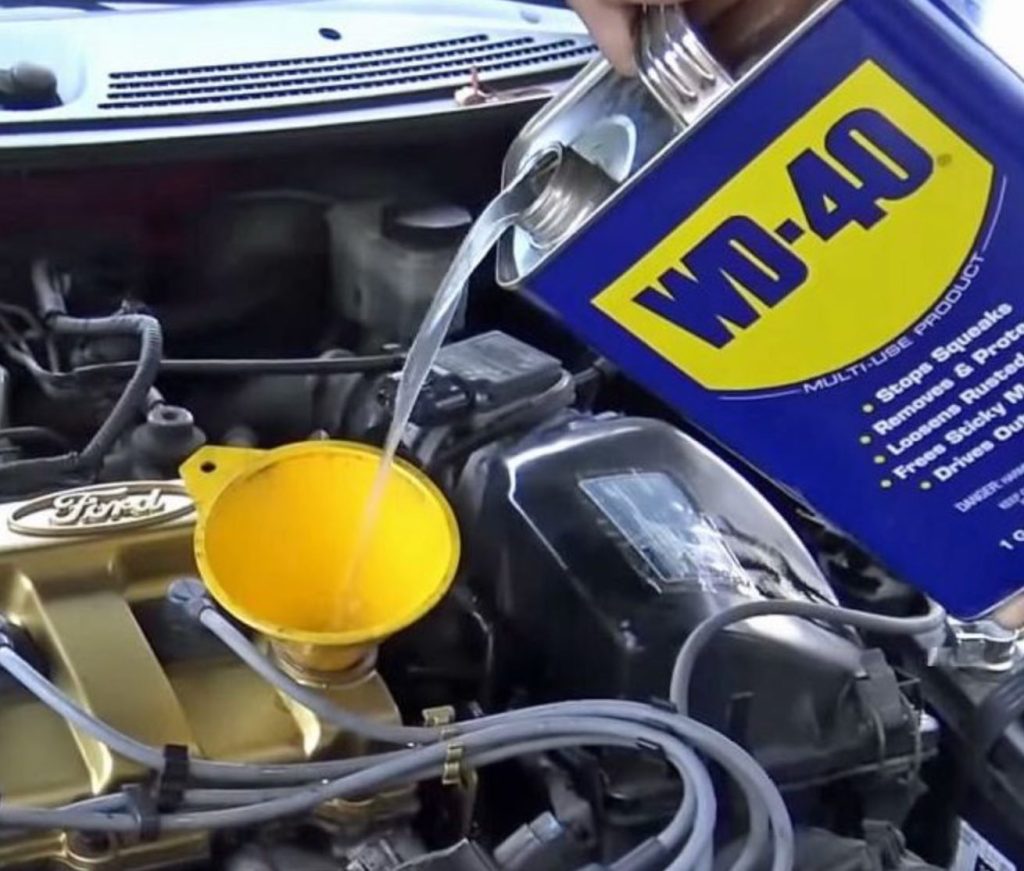

Can we use WD-40 instead of fuel?

Although the precise composition of WD-40 is still a closely guarded secret, the MSDS sheet does identify the ingredients: LVP aliphatic hydrocarbon, aliphatic hydrocarbon, and numerous petroleum base oils. If you did pour WD-40 into the fuel tank, this is what might happen.

WD-40 has ignition point characteristics that are comparable to heavy diesel. It is both combustible and flammable. It can be concluded that adding WD-40 to your fuel tank will cause your automobile to run a little less smoothly and cause more exhaust fumes to come out of the tailpipe.

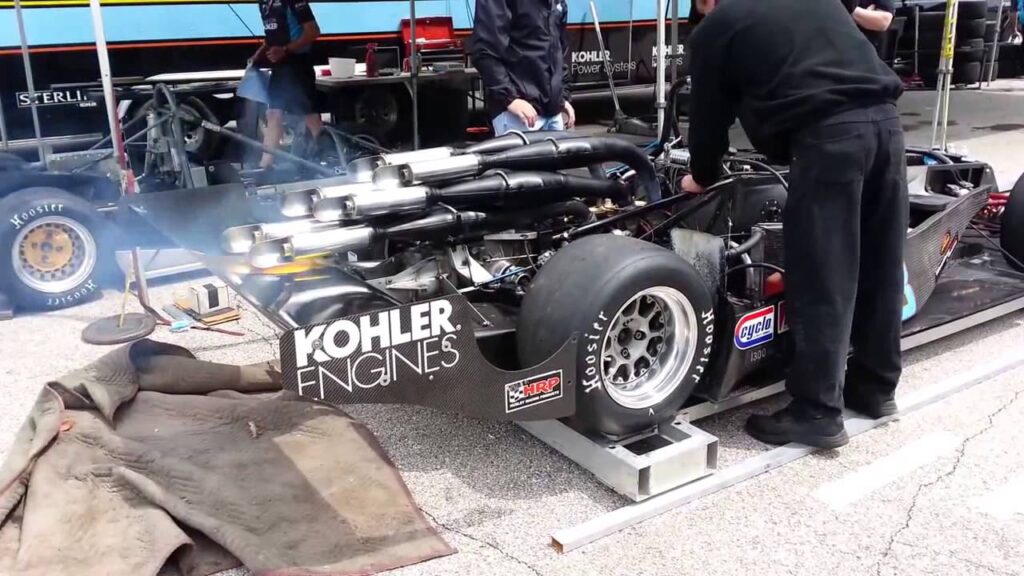

Indy Car engines

Open-wheeled, single-seat racing cars of the IndyCar Series run on an 85% blend of ethanol and gasoline. The racing series is thrilling and unexpected. That’s because the tracks are a mix of urban circuits and ovals. One can’t just skip talking about the Indy car’s potent engines!

These beasts have a power range of 550 to 700 HP. Honda and Chevrolet manufacture the engines used in the NTT IndyCar series automobiles. Depending on the engine manufacturer, these 2.2-liter V6 turbocharged IndyCar engines could generate 550 horsepower and more.

A Rolls Royce aircraft engine?

When Rolls Royce was founded in the early 1900s, aviation engines were its main business. When Rolls Royce sold its “Nene” engine to the Russians in the 1940s, they raised some controversy. The Russians later reverse-engineered the engine. They used that to drive their leading fighter jets during WWII.

After the Wellend and Derwent centrifugal-flow turbojet engines, the Rolls Royce Nene became the third and final type in the line. It used a dual-sided centrifugal compressor and increased turbojet thrust to 5,000 lbf (22.2 kN), which made it an ideal fighter plane engine.

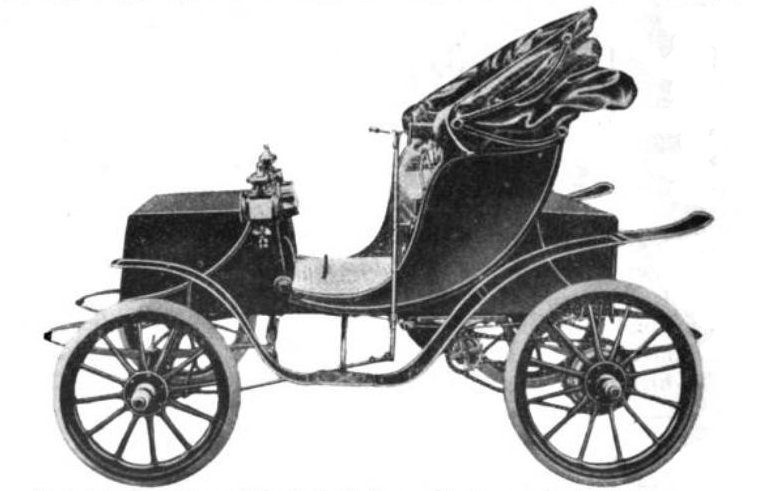

The first hybrid automobile

Gasoline, electricity, and steam were competitors in the early vehicle era, back at the turn of the twentieth century. Each had benefits and shortcomings. Gas was inexpensive in 1916, and tailpipe emissions were unimportant. The hybrid, though, was never about high gas prices or pollution.

It was constructed by Woods Motor Vehicle Company to attract new clients. The company’s electric vehicle sales were declining as more individuals opted for gasoline-powered vehicles. Consumers disputed the claim that it integrated the best features of each. In 1918, both the firm and the car vanished.

Fuel consumption on idle

Despite popular belief, determining how much fuel an automobile engine consumes when the vehicle is idle is a simple task. If you possess an OBDII scanner, it is even simpler. It’s a scanner that can really be synced well with the car’s engine to learn helpful information.

With this scanner, you can learn about the car’s dependability, fuel efficiency, and other crucial components. When a gasoline engine is fully heated up and operating at a speed of 650 to 700 rpm, it typically uses 0.08 to 0.1 gallons of fuel per hour.

How much fuel to start a car engine?

Modern vehicles use a computer-controlled gasoline injection system. It only injects the right quantity of gasoline into each cylinder as required. You only need half a teaspoon of gasoline to start a car engine. This is a reasonable number to keep in mind.

This fluctuates slightly based on the engine’s size, cylinder quantity, and tuning. If the gas tank is empty, pour a gallon of fuel. That ought to be sufficient to activate the fuel pump, which will then send fuel flowing from the tank toward the engine.

Boeing engines and thrust

Boeing has approved the B747-200’s use of GE CF6-50 engines. With a maximum take-off weight of about 356,000 kg or 785,000 lbs, every GE engine can provide over 55k pounds of thrust per engine, or 224k pounds for a short period, all through takeoff.

The engines on the larger B747-400 aircraft have become more potent. A Boeing engine can currently produce a peak of 63,300 pounds of thrust per engine. Because this airplane contains four engines, its overall thrust is a little over 250k pounds.

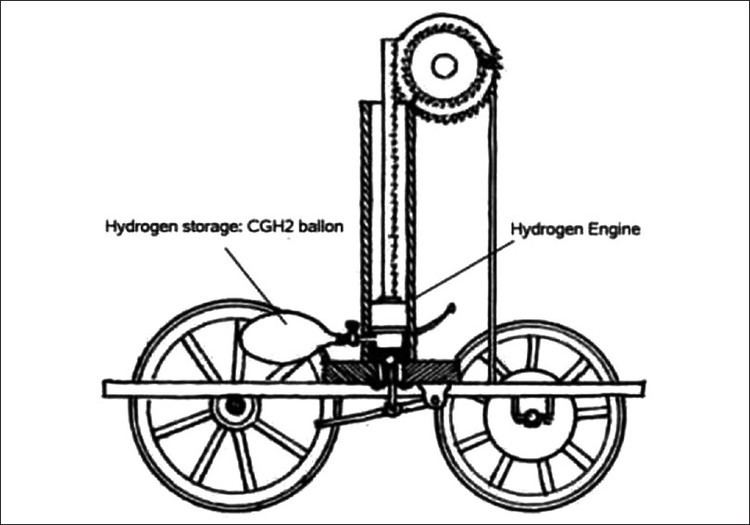

An internal combustion engine-powered car

François Isaac de Rivaz created a hydrogen-powered internal combustion engine featuring electrical ignition and got the patent for his invention back in 1807. He incorporated it into “the world’s first internal combustion powered automobile” in 1808, a crude functional vehicle.

A combo of oxygen and hydrogen was the fuel. An electrical arc physically ignited it. However, the engine didn’t have a crankshaft or connecting rod. A year afterward, Isaac constructed the first automobile that his new engine could drive. Unfortunately for him, his engine never made any profit.

The effect of cold air on your automobile

Many people are unaware of this, but a car engine might perform better when it’s chilly outside. Because cold air is denser and thicker compared to warm air, it causes your car to have more aerodynamic drag. The engine generates more power when it is vented with cold air.

Because of the difference in the air density, a bit more fuel may be fed into the engine, increasing power, even if just slightly. However, this usually only occurs at full blast. You most likely won’t notice it at regular speed and acceleration.

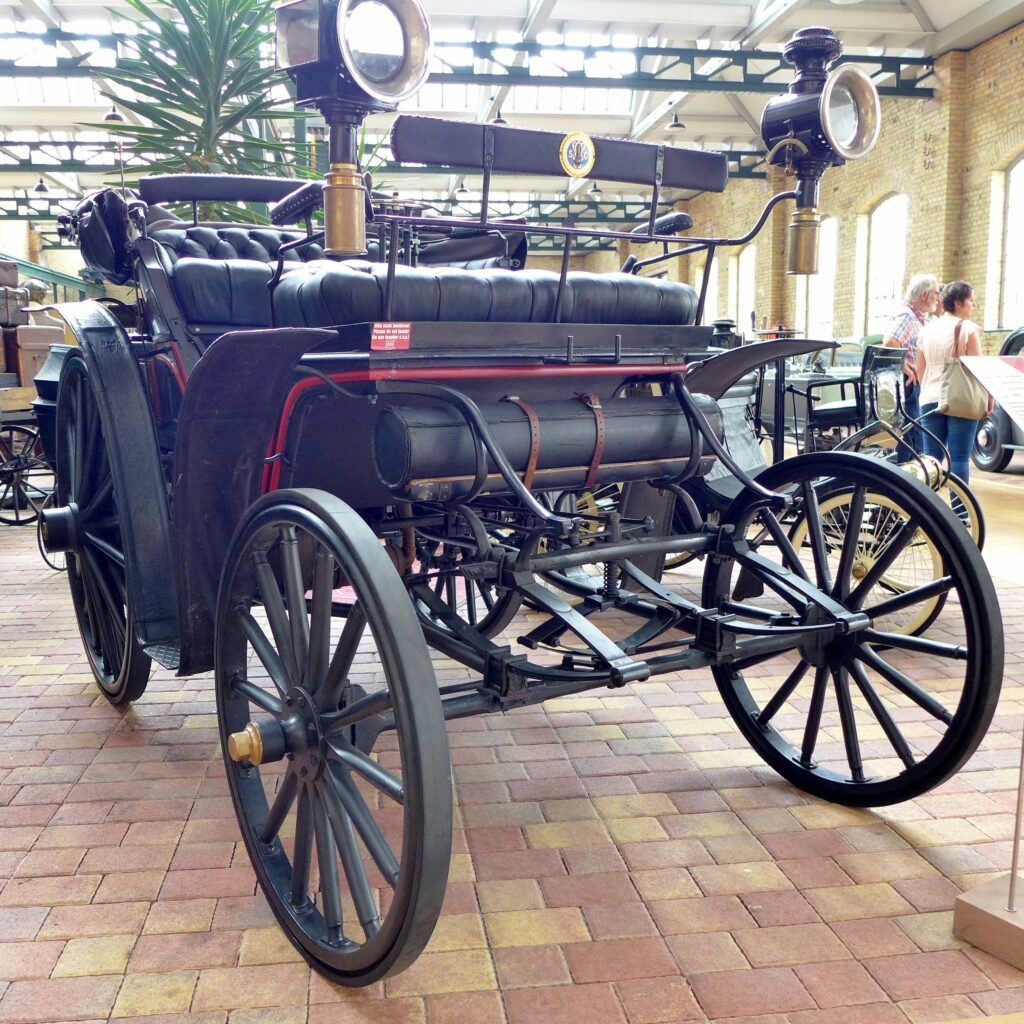

The first self-powered automobile

In 1879, Carl Benz’s one-cylinder, two-stroke stationary gasoline engine made its first operating action. Because of the engine’s business potential, Benz had much more time to work on his vision of a lightweight gasoline-powered car with a frame and engine that functioned as a single unit.

The engine produced 0.75 horsepower (0.55 kW). A regulated exhaust valve, high-voltage electrical vibrator ignition with a spark plug, and water/thermo siphon evaporation cooling were among the specific details. This was the first automobile that generated its own power. A piece of history!

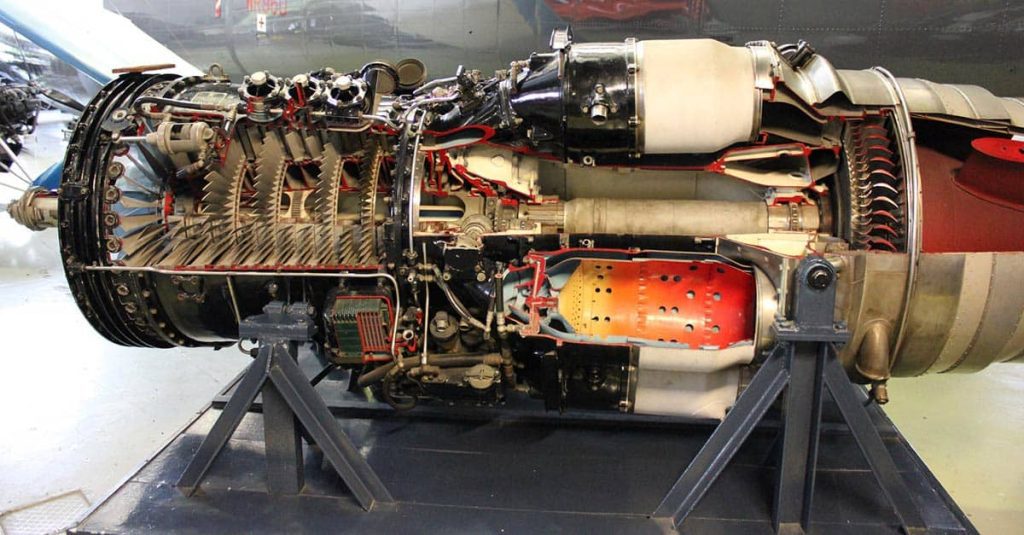

Inside a commercial jet engine

The GE9X engine, being one of the most formidable jet engines currently in existence, has a fan with a diameter of around 134 inches, or 11 feet! The spinning fan’s 16 curved carbon composite blades are now less in count than they were previously.

There used to be 18 or 22 blades present in a fan. The core, the compressor, the low-pressure turbine, and the high-pressure turbine are the four main parts of a turbofan engine. The interior can get as hot as 2400 degrees!

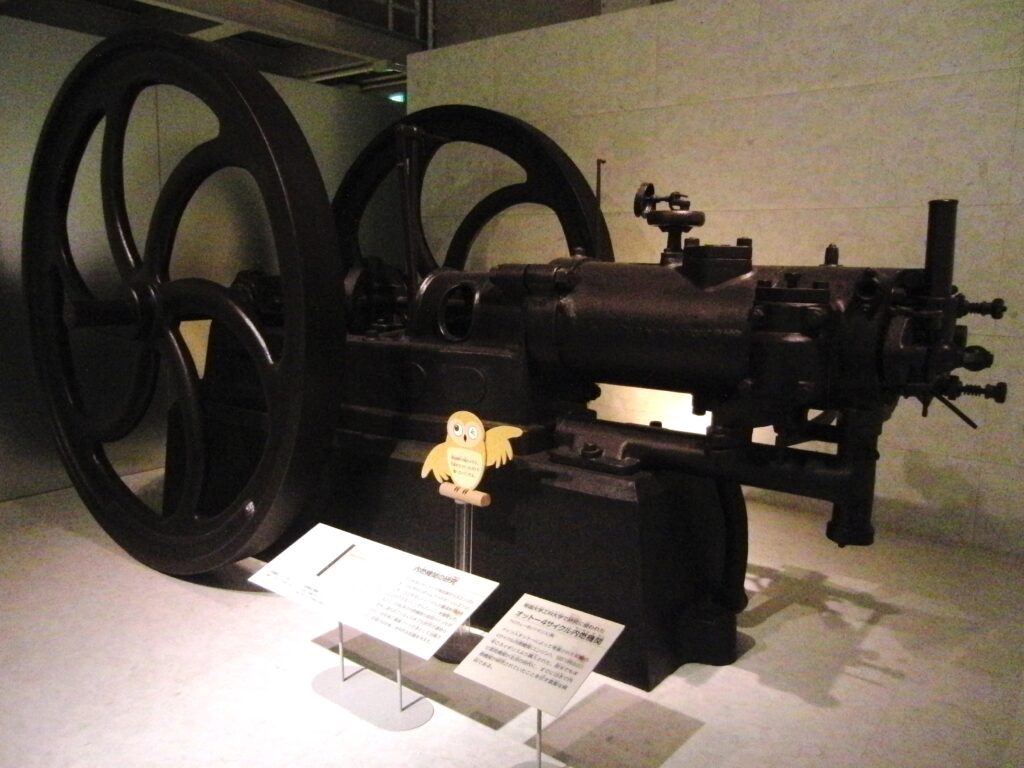

The Otto cycle

By creating the first functional four-stroke engine in 1876, German engineer Nikolaus Otto collaborated greatly with and improved the research of heat engines. It was a fixed engine that operated on a coal gas and air mixture. The design was then refined by Maybach.

By the end of 1876, massive quantities of the engine were being made. The “Otto cycle” is the name of the engine’s cycle. It is among the most prevalent thermodynamic cycles seen in car engines and depicts how a standard spark ignition piston engine operates.

The internal temperature of a car engine

Most autos either convert electricity or burn gasoline to run. In a running car, the temperature within the engine will be extremely high, and it needs up to one hour, maybe more, to come back down to the outside temperature. So, what’s a car’s typical engine temperature?

The average engine temperature varies from 90.5 to 104.5 °C, based on the vehicle. Your engine may have some difficulty initiating when it is too cold. On the contrary, overheated engines may produce smoke that starts fires. So be mindful of that!

What about a commercial jet engine?

Depending on the engine’s region, the interior temperature varies. The isobaric combustor, high-pressure turbine, and low-pressure turbine make up the “hot portion” of a jet engine’s gas core. This, by far, runs at the greatest temperatures. The high-pressure turbine intake temperatures of aircraft gas turbines are approaching 3,600° F!

That is when they are at maximum power. The temperature of the exhaust gas inside the jet pipe soon after the final low-pressure turbine stage will reach almost a thousand degrees Fahrenheit. The temperature of air that leaves the high-pressure compressor portion is around half of that.

The Dodge Viper SRT10 V10 engine

The 8.4-liter aluminum V10 engine that powers the 2008 Dodge Viper SRT10 ups the ante with an incredible 600 horsepower plus 560 lbf of torque. The deep-skirted V10 aluminum engine block of the new Dodge Viper SRT10 was upgraded with a 1-millimeter bigger bore.

This increased the overall capacity to 8.4 liters from 8.3 liters. The block has enhanced water jackets, stronger bulkheads, as well as pressed-in iron cylinder liners for better cooling. It also has cross-bolted main bearing caps for durability and strength.

One of the smallest-ever production engines

The 2008 Tata Nano made headlines not for its parallel twin motor’s modest engine displacement but rather for its extraordinarily low cost. When it was introduced in 2008, it had a $2500 price tag and was made specifically to be inexpensive.

At its inception, the plan to get Indians into an economical car was a good one because the only other options were either a moped or a motorcycle. It had one of the smallest production engines in any car at a 38.1 cubic inch, 0,6L engine.

The Titanic and a Boeing 777

The RMS Titanic could hold 3,500 passengers while weighing approximately 50,000 tonnes. It was renowned across the world as the enormous sea titan before it sank. Its several engines, each capable of producing 46,000 horsepower, were fed by 159 coal burners.

Try comparing it to the Boeing 777. We noted that the combined planned performance of all the Titanic’s steam engines is more than doubled by a single GE90-115B engine, which produces over 110,000 horsepower. And it is evident that that could power a significantly smaller vehicle.

Inner workings of an internal combustion engine

Combustion is the fundamental chemical reaction of producing energy out of air and fuel mixture. It’s sometimes referred to as burning. Inside an internal combustion engine (ICE), the gasoline is ignited and burned inside the engine itself. The energy from this combustion is then partially converted into work.

The engine does this. A stationary cylinder and then a revolving piston make up the engine. The piston is propelled by the expanding combustion gases, which turns the crankshaft. This movement propels the car’s wheels through the powertrain’s gearing system.

The shift from electric to gas engines

The type of buyers drawn to electric vehicles today shares the preferences of early adopters. People valued the reduced reliance on petroleum, low operating and maintenance costs, and a silent ride. Many new automakers tested gasoline-powered and electric engines as motorized cars started supplanting horse-drawn carriages.

Many car manufacturers and owners were quite pleased with the early electrics (also dubbed “juicers“) they tried. Among the best, most costly, and longest-lasting of these companies was Rauch and Lang Electric, a car that exuded luxury and was required for the social elite.

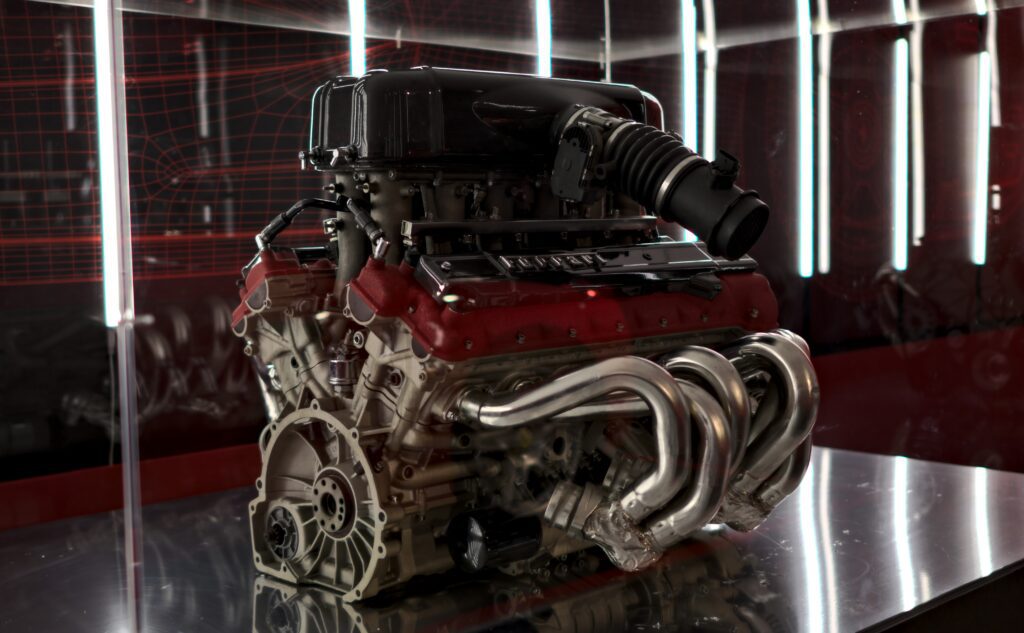

A naturally-aspirated engine

To provide higher power, faster gear shifts, as well as a decrease in aerodynamic drag, the Evoluzione package continuously modifies specifications. The 6.3 L (6,262 ccs) naturally aspirated V12 engine currently generates 509 ft-lb (690 Nm) and 848 horsepower (632 kW) at 9,500 rpm.

Like the FXX, the FXX Evoluzione has a mid-engine design. Power is routed toward the rear wheels using a six-speed sequential semi-automatic transmission with traction control. The bodywork is constructed over a carbon composite tub and an alloy rear subframe.

NASCAR’s engine requirements

Although teams are allowed to innovate and frequently do so, some NASCAR regulations are fairly strict. For instance, the engine must have an iron block and be a carbureted V-8. And they also have tight regulations regarding the method used to bore engine cylinders.

And that’s the process of making them bigger by pulling. Additionally, NASCAR mandates that teams employ blocks, cylinders, and intake manifolds produced from castings supplied by authorized suppliers. The required design further standardizes engines. So it’s not plausible to say that a team has an advantage over others – they’re all the same.

The school bus engine

Without the use of a spark, the gasoline in a diesel school bus engine is ignited by being sprayed with high pressure into an air-filled combustion chamber (or pre-chamber, in the instance of indirect injection) that is heated above the temperature of self-combustion.

The standard school bus must have an engine that produces 550 pounds of torque and 220-300 horsepower. The Ford F-150 has 470 pounds of torque, which is the most torque of any regular pickup as compared with that of a school bus.

The “check engine” light

Automobiles nowadays are mobile computers. Every component has a sensor that transmits data to the engine control module, also known as the engine control unit, which serves as the main computer chip. The O2 sensor has the potential to break down and trigger a check engine light.

Your tailpipe’s oxygen sensor is situated at the front so that it can gauge the amount of oxygen present in the exhaust. An oxygen sensor can survive anything between 60,000 to 90,000 miles on average, although some have gone over 100,000 miles.

All Dodge, little Ford

In 1902, Ford invited the Dodge Brothers to supply most of his components. The Dodges invested tens of thousands of dollars in tools and supplies to start making “running gear” for Ford, which was made up of an axle, an engine, and a transmission put on a frame.

The early Fords’ plans were preserved by the Dodge Brothers, and customers signed deals by going to the Dodge factory. Henry Ford acknowledged that the Dodges produced the whole Ford, except for the body, wheels, and tires, in a 1916 lawsuit brought by the Dodges.

The BMW M5’s silent engine

BMW connected the new stereo system’s digital signal processor (DSP) into the engine’s management system so that the M5’s car radio system could imitate the noise of a twin-scroll, twin-turbocharged V-8 engine in tune with the genuine 560-horsepower mill humming along in the engine bay.

The car stereo will simulate the sounds that you’d typically miss from the driving seat through the speakers as you crank the engine or accelerate away from a traffic signal. You would think that with this much capacity, the engine wouldn’t require any help in making noise.

Breaking the speed record

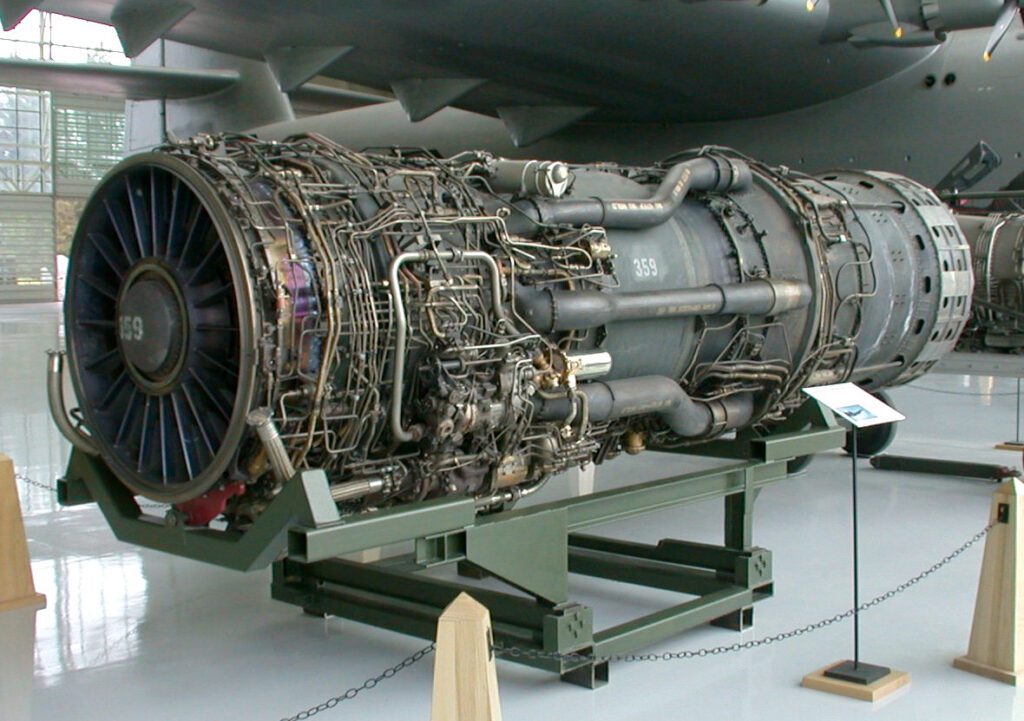

The SR-71 was powered by Pratt & Whitney J58 turbojet engines that were built to maintain Mach 3 speeds at altitudes of more than 80,000 feet. The J58 was an incredible feat with a single-shaft rotor structure, and a cutting-edge compressor bled bypass while operating at extremely high speeds.

The six bypass tubes, which diverted airflow from the compressor stage straight into the afterburner, were what gave this engine its special appeal. With its full afterburner on, the SR-71 was able to run at a fuel efficiency that was considerably higher than that of previous after-burning jet engines.

The race car with a helicopter engine

Every race car has the peculiar function of taking us somewhere else, of overwhelming us with ludicrous feelings and unreal pleasures. No other rally car of the 20th century performed that feat as spectacularly as the 1967 STP-Paxton Turbo car. Engineer Ken Wallis created the jet car idea.

This idea was rejected by legendary racers Dan Gurney and Carroll Shelby before settling down with Andy Granatelli. This little Pratt & Whitney turbine power plant could have been aboard a corporate jet or a chopper. Rather, it sat next to driver Parnelli Jones.

The first American jet engine

The first jet aircraft built in America was the XP-59A. Even though it was never used in battle, it gave the Air Force and U.S. Navy vital expertise in modern jet tech and opened the door for more sophisticated designs.

The Messerschmitt Me 262 jet fighter and the Arado Ar 234 jet bombe – both of which can be found in the NASM collection – became active. Germany became the world leader in jet-powered aircraft. But the tech was just so new it had no discernible impact on the conflict.